What companies like about the small industrial robot

As markets change with consumer tastes and preferences, it is important that companies invest in a technology that will enable them to keep up with the changes. A technology that will afford them the nimbleness and speed of lightning in meeting the new tastes and product demands.

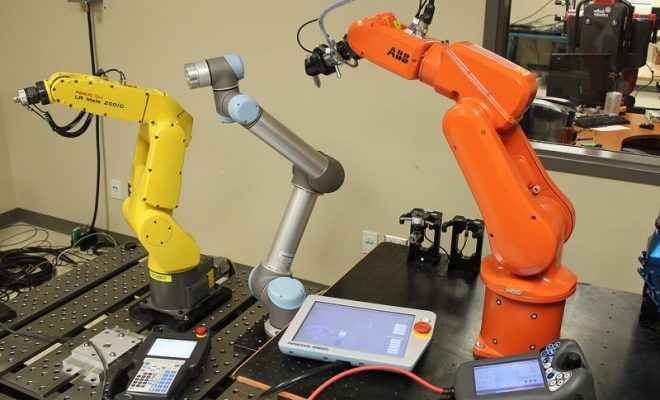

A key technology that companies can adopt to meet face and solve this challenge, is acquiring collaborative robots. These are industrial robots, that work just as their name suggests, collaboratively! With both people and other collaborative robots.

Here are some of the reasons why these robots have become very popular with manufacturers.

Size

Modern industrial robots are often also referred to as small industrial robots. They are compact and can be used in any factory size. Due to their size, they can be easily carried around the factory to perform different tasks.

Their small size also allows them to be mounted anywhere in the factory. They can be mounted on tabletops, floors and even ceilings. They can also be easily carried around.

Weight

Collaborative robots are quite easy to carry around. This is not because they are small, but as part of their design.

This ensures that they can be easily moved from one point to another. They are made out of light weight material to ensure that they are easy to carry to around.

Safety

Another aspect of small industrial robots that manufacturers like is how safe they are to use. Traditional robots were completely unsafe. They have caused numerous fatal and non-fatal workplace injuries.

Small industrial robots are designed with light material so that if you accidentally bump into it, it will not harm you. Further, they have rounded edges to ensure that you will not be injure if you collide with it. Also, these robots can sense human presence near them and stop all their work until the presence is minimal.

Faster deployment

Again, unlike traditional robots, the small industrial robots are ready to go on the first day they arrive at your premises.

It takes a very short time to assemble one of these robots. To get the traditional robots to start working at the factory would sometimes take months as space was prepared and assembly was a complicated process.

Speed

With the collaborative robots, production process take place faster than before. When it comes to production, collaborative robots are faster than a team of human workers at any factory floor.

Once a collaborative robot is introduced into the factory, a lot of things change. With roobts working without need the need for breaks, you are sure that your company’s production rate changes completely.

You are able to produce at all times, much faster and affordably than you could have had you added your workforce.

Lower cost of the end product

With speed and large cost savings in the production process, manufacturers have no choice but to pass the benefits on to their customers. As a result, you will find that the price of goods produced with this technology goes down.

This enables the company to sell more of their product and thus help improve the financial bottom line of the organization.

Quick return on investment

Another unique aspect of the collaborative robot, is that whether you acquire it through purchase or pay for it by the hour, you will definitely experience a faster return on investment.

This happens once you begin selling your products. Due to the robotic manufacturing process, you have a better-quality product produced at a lower cost. This attracts more customers and eventually more money into your business. This then ensures a quick return on your investment in the robot.

Conclusion

Small industrial robots are a favorite for all who acquire them. They enable small manufacturing companies get into the market and compete effectively even with companies much larger than themselves. They not only benefit the individual manufacturer but also benefit the customer and even whole sectors of the economy where they are used.